In the realm of heavy construction and earth-moving endeavors, the excavator carrier roller stands as a key yet often overlooked component, integral to the seamless functionality of your machinery.Positioned at the top of the undercarriage, carrier rollers support the track chain and deliver the tension required to avoid slacking and sagging. This ensures the excavator maintains optimum contact with the ground and facilitates consistent movement and stability, which is crucial when navigating uneven and rugged terrains.

Unpacking the Significance of Excavator Carrier Rollers

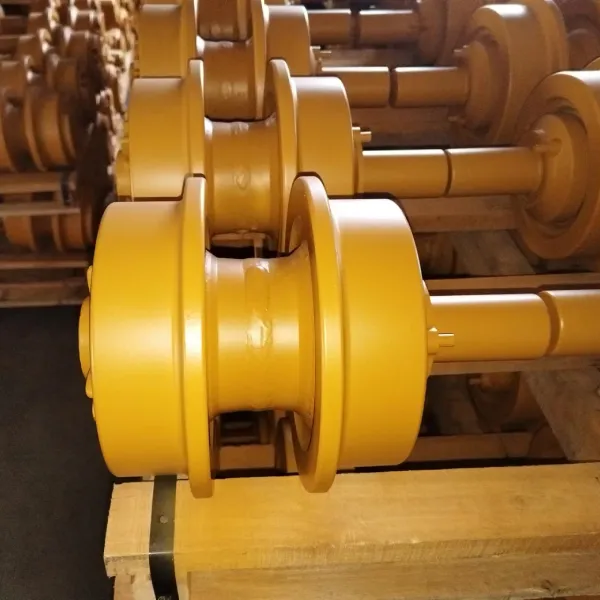

For the endurance and long-term performance of heavy machinery, nothing is more vital than the use of high-quality excavator carrier rollers. These components are meticulously designed to withstand the daily challenges and strains of operation. Constructed from toughened materials, many of these crucial components come sealed and lubricated, offering additional defense against the intrusion of dirt, dust, and water. The robust design serves to prolong the life of both the rollers and the undercarriage system they support, significantly trimming maintenance expenses and enhancing the excavator’s reliability. Investing in superior carrier rollers means investing in the sustained peak performance of your excavation equipment.

Excavator carrier rollers, integral parts of an excavator’s undercarriage, function to support the upper portion of the track chain, distributing weight evenly and facilitating smooth operation over varied terrain. The SD16 and D65 models, renowned for their robust design and versatility in challenging work environments, necessitate carrier rollers that can withstand immense loads and resist wear from abrasive elements. These components are instrumental in preserving the machine’s structural integrity and ensuring uninterrupted operation.

Partnering with the Right Supplier for Your Undercarriage Needs

Choosing the appropriate suppliers for your excavator undercarriage parts is a decision that carries significant weight for the operation and maintenance of your heavy machinery. The undercarriage, being so fundamental to an excavator’s functionality, demands only the highest quality components to preserve its strength and reliability. Each part, especially pivotal ones like the carrier roller, must undergo careful selection to maintain the machinery’s performance and extend its service life. By partnering with suppliers known for their durability and dependability in providing undercarriage parts, you safeguard the operational integrity of your machinery, ensuring productivity remains high and downtime low.

The CARRIER ROLLER SD16 D65 is consummate.

Taking a specific example, the CARRIER ROLLER SD16 D65, which is designed for use with certain dozers and excavators, showcases the importance of selecting a part that is crafted to meet the demands of your equipment’s specifications. With the right carrier roller, like the SD16 D65, machines gain a boost in track life and efficiency, translating to enhanced reliability and reduced operational downtime.

A proper analysis of such a component provides clear insights into your equipment’s functionality and reinforces the importance of sourcing from a supplier that understands the complexities of these machines and offers superior aftercare support. By investing in top-quality parts backed by expert guidance, heavy machinery operators can ensure their excavator’s uptime and longevity significantly improve.

Finding and implementing the best excavator carrier rollers plays a pivotal role in the maintenance and efficiency of heavy machinery. By doing so, and with the support of seasoned excavator undercarriage parts suppliers, excavation professionals can ensure their equipment, like models requiring the CARRIER ROLLER SD16 D65, operates at its best, providing reliability and durability in the most demanding of projects.